The Nightmare Hidden Costs of Scaled PHE's

Scale acts as an insulator, reducing the heat transfer temperatures between the primary and secondary heat sources. This in turn, requires more power to reach the required temperature of 60°C, resulting in significantly higher energy costs. Add to this, unhappy customers with lower temperatures of DHW coming through the showers, plus the increase in CO2 emissions and your carbon footprint, and things aren’t looking too good! And just when you think things couldn’t get any worse, there is a real risk of legionella, which develops above 20°C and below 50°C. Scale not only helps to accelerate legionella growth but gives it a place to live!

The client was concerned about the rising energy costs and a low DHW temperature.

The solution

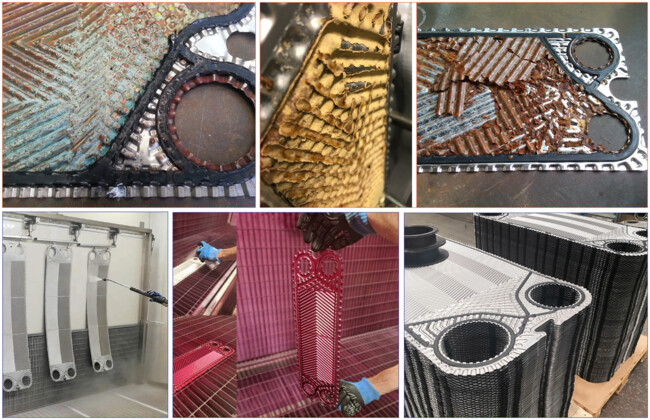

Inevitably, the efficiency of plate heat exchangers (PHEs) diminishes over time, due to the accumulation of deposits like calcium carbonate, calcium sulfate, magnesium and silica, which builds up on the heat exchanger surfaces, preventing efficient heat transfer. Furthermore, contributing factors, such as high temperatures, low fluid velocity and turbulence, the hardness and pH of the water and bad flow distribution over the heat surfaces, will also increase the likelihood of scaling.

The effects of scaling can be seen in the deterioration of the efficiency of the PHE, as it demands more energy consumption to give the same or a lesser output of heat, as well as increasing operational running costs. It can also affect temperature control, cause resistance in heat transfer and eventually corrode and damage the Plate Heat Exchanger. Regular cleaning of the plate packs is therefore essential to maintain the heat transfer coefficient.

Our engineers attended the sites, opened the heat exchangers and removed the existing plates and gaskets. As the plate packs were quite small, we just replaced them as required. Also, each site had a different size plate or manufacturer, so each one had to be sourced and ordered accordingly.

We recommended to the customer a combination of regular preventative maintenance to ensure consistent high efficiency and maximum heat exchanger life, before the effects of scaling get established.

If the plates had been larger and had the same manufacturer, we would have recommended using our rotating plate pack solution with this service, to enable new plates and gaskets to be fitted within 1-3 hours, as no cleaning or regasketing is required. In the meantime, the old plates would be removed for cleaning and regasketing and held ready for the next service, where the process will be repeated. Using rotating plate packs allows downtime to be kept to a few hours, rather than the 1-2 weeks that would normally be required to refurbish the plates.

In critical applications, heat exchanger failures can cost thousands of pounds every day. Adopting the rotating plate pack system means you have a spare plate pack ready to install if a heat exchanger fails unexpectedly. This can be vital, especially as the lead time for spare parts can be several weeks for some heat exchangers, and if your plates don’t pass the dye penetrant test and new plates aren’t in stock, downtime can be even longer. This is particularly cost effective if you have several heat exchangers on site with identical plate packs, as just one rotating pack can be used to service many heat exchangers.

You can also return the complete plate heat exchanger, to our works, for refurbishment. This service will also include a full hydraulic pressure test, complete with test certificate, before the heat exchanger is returned to site.

Our refurbishment programme includes Pre-Clean & Initial Inspection, followed by the dipping of heat transfer plates in a series of chemical baths to remove deposits and scale, before been completely rinsed with clean water and visually inspected for a second time. Dye penetrant testing follows, where the cleaned plates are sprayed with a fluorescent dye and inspected with an ultraviolet lamp, for pit corrosion, pin holes and cracks.

During the regasketing process, the gaskets are tapped to the plates and stacked to minimise gasket movement, before heat transfer plates with glued gaskets are placed inside a temperature-controlled oven for curing which eliminates gasket movement during the final assembly. The plates are installed in the plate heat exchanger frame by trained service engineers, due to specific heat transfer plate arrangement and completed with a full hydraulic pressure test been carried out.

Plate Heat Exchanger Service & Replacement

Contact Us

Hatters Lane, Watford, Hertfordshire, WD18 8AJ