Plate Heat Exchanger Plates

By utilising our global supply chain, we are able to supply genuine heat transfer plates for all types of plate heat exchanger. Combined with the holding of extensive stocks, this enables us to keep prices competitive and keep lead times to a minimum. Non-genuine plates are also available for some models if required.

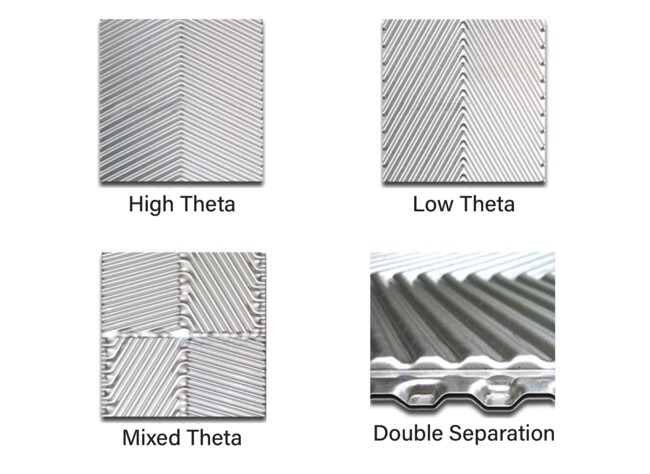

A plate heat exchanger is designed to give the best thermal efficiency, with a specific combination of high and low theta heat transfer plates. To maintain the correct duty, it is important that the same type of plates are used and installed in the correct order. Each plate heat exchanger is supplied with a plate configuration sheet, which contains all the relevant information for ordering spare parts and rebuilding the plate pack.

Heat Transfer Plate Arrangement

Every plate heat exchanger is different, so to maintain the correct duty, it is important that the same theta plates are used and are installed in the correct order. Each is supplied with a plate configuration sheet, containing the relevant information for ordering spare parts and rebuilding the plate pack.

Before being returned to the customer, every heat exchanger plate pack we service, is arranged in the correct order, ready for installation by on-site engineers.

Heat transfer plates are available in different materials and thicknesses, depending on the manufacturer. The three main materials used are as follows:

304 Stainless Steel

This is the lowest cost heat transfer plate material. It has a low corrosion resistance and is usually only available in a thickness of 0.4mm. This type of heat transfer plate is typically used on HVAC applications.

316 Stainless Steel

This is the most common heat transfer plate material, used in many applications. 316 stainless steel has a high corrosion resistance and is typically available in thicknesses from 0.5mm up to 0.8mm.

Titanium

This has a very high resistance to chemical attack, including most acids, chlorides and chlorine chemicals. Titanium is usually available in thicknesses from 0.4mm up to 0.6mm. Other materials, such as Hastelloy and SMO, are available on request for special applications.

Double Wall Safety Plates

These plates consist of two thin heat transfer plates which are welded together around the ports, creating an air gap between them which acts as a safety barrier if plate failure occurs, as the fluid in the failed channel will leak to the atmosphere, giving a visible indication of failure and avoiding fluid cross-contamination.

Double Wall typical applications include, Food processing, Dairy Industry, Breweries and the Chemical Industry.

Contact Us

Hatters Lane, Watford, Hertfordshire, WD18 8AJ