Plate Heat Exchanger Gaskets

Heat Exchanger Spares.com supply replacement heat exchanger gaskets for ALL plate heat exchangers.

All plate heat exchanger gaskets are manufactured in accordance with a rigorous quality control procedure. With our gasket testing facilities, we are able to fully inspect gaskets to ensure they continuously meet our high standards. For this reason, we are able to offer a 12 month warranty (subject to conditions) on all plate heat exchanger gaskets supplied by us.

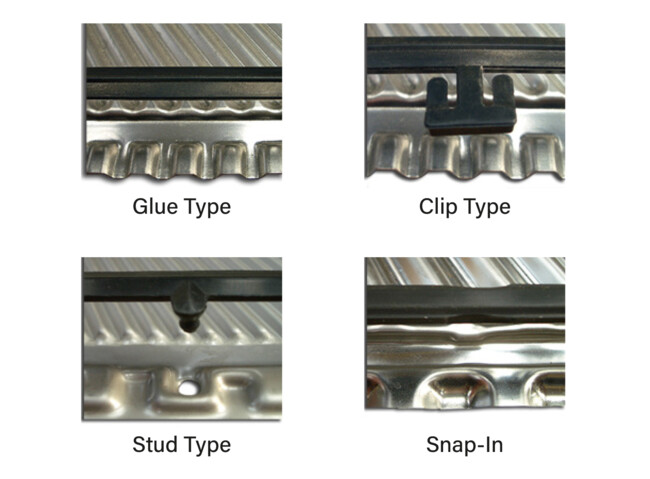

Depending on the heat exchanger manufacturer and model type, the heat exchanger gaskets are fixed to the heat transfer plates either mechanically or with an adhesive.

The common attachments are listed below. For more detailed information select a specific manufacturer.

Types of Adhesive Attachments

Contact Adhesive

This is the most typical adhesive method. After assembly, the glue is often oven cured to ensure a good bond. However, the gaskets can normally be removed by hand, leaving behind a small amount of glue in the gasket groove.

Two Part Epoxy Resin

This process uses a hardener to complete the curing process. This forms a superior bond which stops the gasket from being easily removed from the heat transfer plate.

Double Sided Tape

This process is used to hold long pieces of straight gasket on larger plate heat exchangers. It would not be used to hold the entire gasket to the heat transfer plate.

Mechanical Attachment

Most modern plate heat exchangers use a form of mechanical attachment to fix the gaskets to the heat transfer plates.

- Pros. The gaskets can be easily removed and replaced, especially on site, as the gasket sealing area remains clean (free from glue residue).

- Cons. The gaskets will become detached from the heat transfer plates when pressure washing on site or through incorrect / rough handling. Care must be taken when tightening the heat exchanger, to ensure the gaskets remain in the gasket groove. Occassional checks should be made whilst tightening down, so any gaskets that have moved out of the groove can be pushed back in.

Types of Mechanical Attachment

Clip Type

The heat exchanger gasket is positioned on the heat transfer plate and held in place by clips, at specific areas around the edge of the plate.

Stud Type

This is similar to clip type, but instead of attaching to the edge of the heat transfer plate, part of the gasket (stud) is pushed through the plate, using a specific tool.

Snap In

The gasket is positioned on the heat transfer plate. At specific points the gasket groove has narrow sections, which the gasket is pushed (snapped) into.

There is a variation of this in some older gaskets, where the gaskets have holes at certain points in the back of the gasket. These holes are pushed onto a ‘ball’ manufactured into the gasket groove, thereby holding the gasket in place.

Contact Us

Hatters Lane, Watford, Hertfordshire, WD18 8AJ